In this paper we discuss a framework for capacity planning and lead time management in manufacturing companies, with an emphasis on the machine shop. First we show how queueing models can be used to find approximations of the mean and the variance of manufacturing shop lead times. These quantities often serve as a basis to set a fixed planned lead time in an MRP-controlled environment. A major drawback of a fixed planned lead time is the ignorance of the correlation between actual work loads and the lead times that can be realized under a limited capacity flexibility. Ecard Software For My Website. To overcome this problem, we develop a method that determines the earliest possible completion time of any arriving job, without sacrificing the delivery performance of any other job in the shop. Pika Software Builder Full there. This earliest completion time is then taken to be the delivery date and thereby determines a workload-dependent planned lead time.

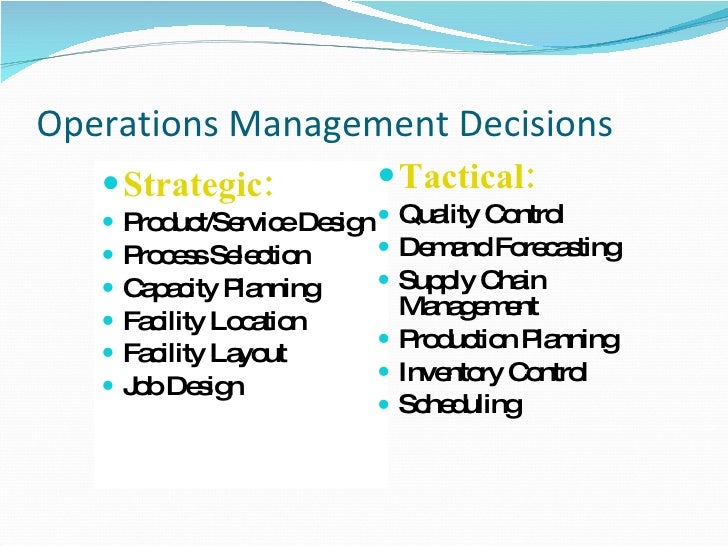

Process planning and operations scheduling Production management I. The function of scheduling and capacity planning is deadline-oriented planning and control of. Bangladesh Open University Production Operations Management Page- 205 Lesson One: Capacity and Capacity Planning Lesson. Mustek 2448ta Plus Driver Mac here. Capacity Planning – Importance. To the widening of the scope, the name was changed from production management into operations management.